Introduction

"From a little spark may burst a flame" by Dante Alighieri, Rightly said that a spark is required to start a flame and in automobile since there is a conversion of chemical energy (i.e. air-fuel mixture) into mechanical energy i.e. (crankshaft rotation) spark is essential which is responsible for the combustion, but from where does this spark comes? How does the timing of spark and prepared air-fuel mixture is managed? Let's just dig it out.

In an internal combustion engine, combustion is a continuous cycle and occurs thousands times in a minute so an effective and accurate source of ignition is required. The idea of spark ignition came from a toy electric pistol that used electric spark to ignite a mixture of hydrogen and air to shoot a cork.

The electronic ignition system is the type of ignition system that uses electronic circuits, usually by transistors controlled by sensors to generate electric pulses which in turn generate the better spark that can even burn the lean mixture and provide better economy and lower emission.

Why Electronic Ignition System?

Various types of ignition systems were used lately that are

1. Glow plug ignition system,

2. Magneto ignition system

3. Electric coil or Battery ignition system,

But all these systems have their own limitations that are:

Glow plug ignition system is the oldest of all and is obsolete because of its many limitations-

Glow plug ignition system has a problem of causing uncontrolled combustion due to the use of electrode as a ignition source, which is solved later after the introduction of Magneto ignition system in which electrodes are replaced by spark plug. Unlike magneto ignition, Glow plug produces high exhaust emission due to the incomplete combustion.

Magneto ignition system:

It is the system introduce to overcome the limitations of old ignition systems, but it has its own limitations-

- It depends on the engine speed, so shows starting problem due to low speed at the starting of the engine, which is later solved with the introduction of Battery coil ignition system in which battery becomes the energy source for the system.

- Expensive than electric coil ignition system.

- Wear and tear is more than battery coil ignition because of greater number of mechanical moving parts than battery coil system.

- Can cause misfire due to leakage.

Also Read:

- What is CVT – Continuously Variable Transmission and How it Works?

- How Anti-lock Braking System (ABS) Works?

- Different Types of Engine

Electric coil ignition or Battery ignition system

– System is the latest of all above and is being used from long time due to its better efficiency and accuracy but it also shows some limitations-

- Less efficient with the high speed engines

- High maintenance required due to mechanical and electrical wear of the contact breaker points

So, Since in the modern automobile new technologies are introduced and it is found that use of sensors and electronic component gives more effective and accurate outputs than that of mechanical components so the use of sensors with electronic controlled unit becomes essential to fulfill the needs of modern high power and high speed automobiles or hyper series of automobiles, so to fulfill the need for high performance, high mileage and greater reliability has led to the development of Electronic ignition system.

Main Components

1. Battery

It is the powerhouse of the ignition system as it supplies the necessary energy to the ignition system.same as battery coil ignition system.

2. Ignition Switch

it is the switch used in ignition system which governs the ON and OFF of the system ,same as the battery coil ignition system.

3. Ignition Control Module or Control Unit of Ignition System

It is the brain or programmed instruction given to the ignition system which monitors and control the timing and intensity of the spark automatically. It is the device that receives voltage signals from the armature and set the primary coil to ON and OFF ,it can be placed separately outside the distributor or can be place in electronic control unit box of the vehicle.

Also Read:

- Torque Converter Working, Principle, Main Parts and Application

- How DTSi Engine Works – Explained?

- Top 5 Best Vacuum Cleaner for Car to Buy

4. Armature

Contact breaker points of battery ignition system is replaced by an armature which consists of a reluctor with teeth (the rotating part), vacuum advance and a pickup coil(to catch the voltage signals),Electronic module receives the voltage signals from the armature in order to make and break the circuit, which in turn sets the timing of the distributor to accurately distribute current to the spark plugs.

5. Ignition Coil

Same as the battery ignition coil system ignition coil is used in electronic ignition system to produce high voltage to the spark plug.

6. Ignition Distributor

As the name indicates it is the device use to distribute the current to the spark plugs of the multi cylinder engine.

7. Spark Plug

The spark plug is used to generate spark inside the cylinder.

Working of Electronic Ignition System

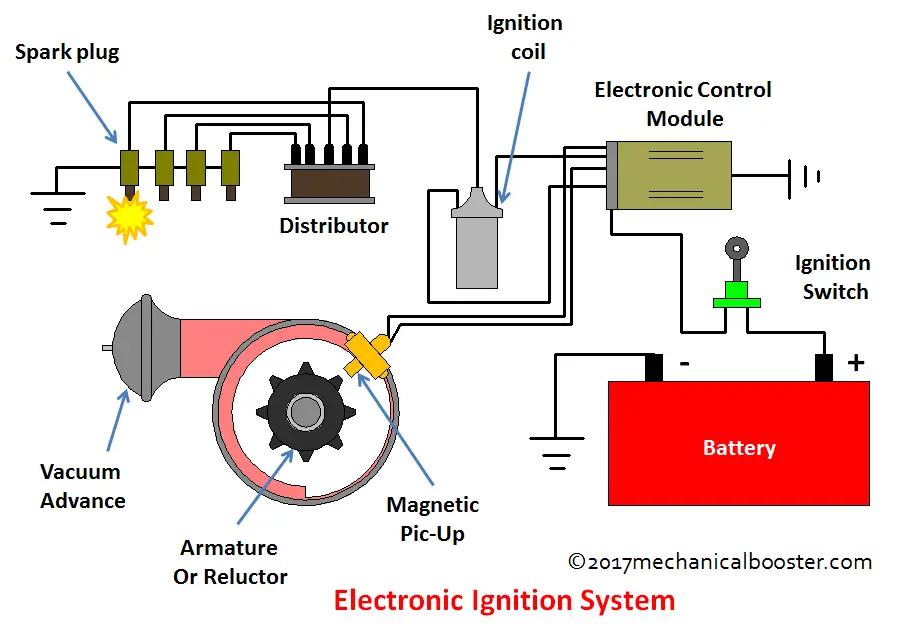

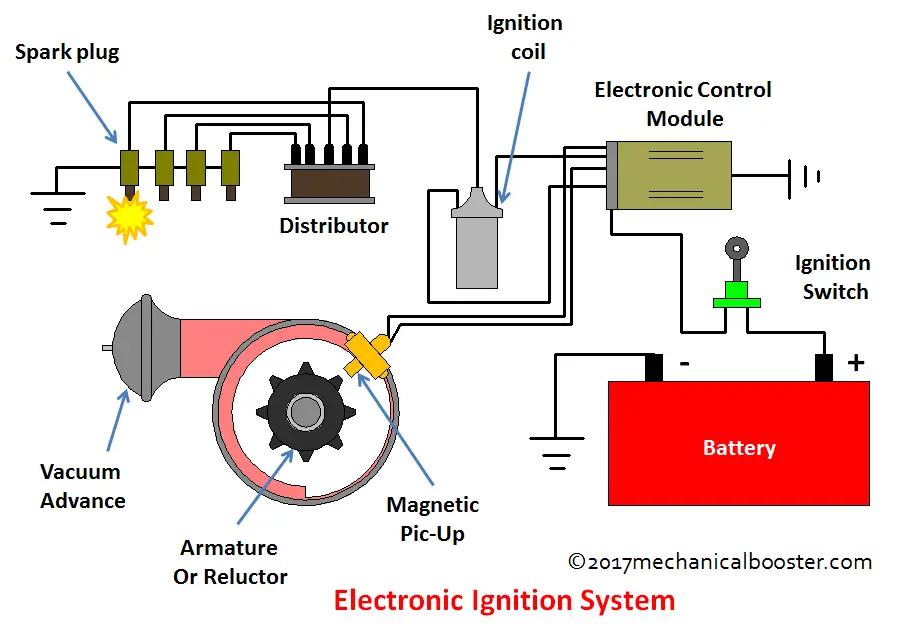

- To understand the working of the electronic ignition system let's consider above figure in which all the components mentioned above are connected in their working order.

- When the driver switch ON the ignition switch in order to start a vehicle the current starts flowing from the battery through the ignition switch to the coil primary winding, which in turn starts the armature pickup coil to receives and send the voltage signals from the armature to the ignition module.

- When the tooth of the rotating reluctor comes in front of the pickup coil as shown in the fig the voltage signal from pickup coil is sent to the electronic module which in turn senses the signal and stops the current to flow from primary coil.

- When the tooth of the rotating reluctor goes away from the pickup coil, the change in voltage signal is sent by pickup coil to the ignition module and a timing circuit inside ignition module turns ON the current flow.

- A magnetic field is generated in the ignition coil due to this continuous make and break of the circuit which induced an EMF in secondary winding which increases the voltage upto 50000 Volts.

- This high voltage is then sent to distributor ,which has the rotating rotor and distributor points which is set according to the ignition timing.

- When the rotor comes in front of any of those distributor points the jumping of voltage through the air gap from the rotor to the distributor point takes place which is then sent to the adjacent spark plug terminal through the high tension cable and a voltage difference is generated between the central electrode and ground electrode which is responsible for generating a spark at the tip of the spark plug and finally the combustion takes place.

For better explanation watch the video given below:

Application

- The electronic ignition system is used in modern and hypercars like Audi A4, Mahindra XUV-500, etc.and bikes like ktm duke 390cc, Ducati super sports etc. to meet the high reliability and performance need .

- It is also used in aircrafts engine due to its better reliability and less maintenance

Source: https://www.mechanicalbooster.com/2017/11/electronic-ignition-system.html

Posted by: cianoanastasianoes.blogspot.com

Posting Komentar